A radial drilling machine is a tool that is designed to drill holes into very strong materials which can seldom be performed by ordinary drilling machines. These tools can make holes of different sizes too. Compared to the conventional machines, these tools offer a greater precision and stability.

These devices are widely used in metal fabrication industries as it offers precision to bore holes in different sizes on tough metals. As most of the conventional drilling machines are quite unstable, it can seldom offer the required stability and strength. These machines are often used with a CNC router which further simplifies its usage and efficiency. CNC controlled devices can be operated with experience as the tool is capable of a wide variety of tasks.

- Radial drills are designed for medium to large and heavy work pieces and bulky objects.

- The material that the machine can process on are : mild steel, metal, stainless steel, cast iron, aluminum, copper, etc. except magnesium alloy as its processing may cause fire.

- The machine is having a vertical column mounted on the large base. The column is supported by radial arm which can be raised or lowered to accommodate work pieces of different heights.

- The arm can swing horizontally to any position around the column over the work.

- These movements in a radial-drilling machine when combined together permit the drill to be located at any desired position.

- When two or more holes are to be drilled in a work piece, the position of the arm and drill head is altered so that drill spindle can be moved from one hole to another without altering the setting of the work.

- Plain Radial Drilling Machine.

In this type the arm is having vertical and horizontal movement of the drill head along the arm and circular movement of the arm in horizontal plane about the vertical column.

- Semi Universal Radial Drilling Machine.

In this type of radial drilling machine, in addition to the above three movements the drill head can be swung about the horizontal axis perpendicular to the arm. This permits to drill a hole at an angle to the horizontal plane.

- Universal Radial Drilling Machine.

In this drilling machine in addition to above four movements, the arm holding the drill head can be rotated on the horizontal axis. All these movements in radial drilling machine enable to drill on a work piece at any desired place at any angle.

- Amount of area that it can cover which is only dependent on the length of the arm.

- Considerable size of work that it can handle since the arm can actually swivel out of the working area allowing cranes and derricks to place work pieces on the table.

- Less effort is required during the drilling process because the arm assembly seemingly is doing all that is needed for specific tasks to be completed.

- The tasks that a radial drilling machine can do include all drilling operations like boring holes, Reaming, countersinking, counter boring, tapping and spot facing.

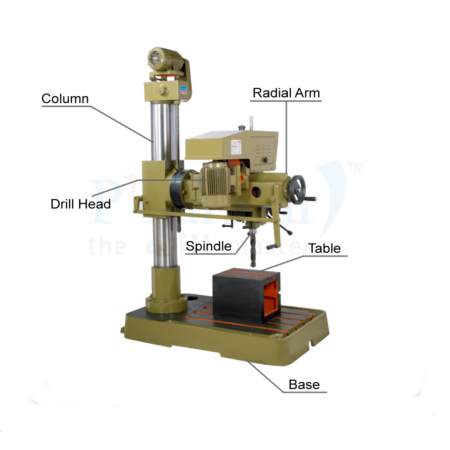

- Base

Base of the radial drilling machine is a rectangular casting and is support column at one end. The other end is finished and provided with “T” slots to hold the table or work pieces.

In some radial drilling machines two bases are provided for setting jobs for mass production. Loading or unloading can be carried out on one base while drilling operation is carried out on another.

- Column

It is mounted at one end of the base. It is a cylindrical casting and supports the radial arm which slides up and down. A motor is mounted on the top of column which imparts vertical movement to the radial arm by rotating a screw passing through a nut attached to the radial arm.

- Radial Arm

It is mounted on the column and extends horizontally over the base. The face is accurately machined and drill head slides over it. It can be swung around the column. In some modern machines a separate motor controls the radial arm.

- Drill Head

The drill head is mounted on the radial arm and it drives the spindle. It is having mechanism for different speeds and feeds. The drill head slides over the radial arm for adjusting the position of the drill. The drill head can be clamped at any position on the radial arm after sliding.

- Spindle Drive and Feed Mechanism.

In some radial drilling machines a motor is mounted at the overhanging arm. The motion is transmitted to the drill head by bevel gears through a train of gears in drill head the spindle speeds and feeds may be adjusted. In some machines the motor is mounted directly on the drill head.

- Have only sophisticated or experienced personnel to perform the machine operation or maintenance.

- Basically, only one person is needed to serve. If more than one person is called for, good communications is required.

- Read and understand the operation manual thoroughly before operation.Place the manual close to the machine for easy access.

- All operation and maintenance personnel need to know the location of the emergency switch, its function and operation.

- Switch off the power supply before movement and installation.

- Don’t touch any switch with wet hand.

- Make sure that the slings are strong enough to lift the machine

- Make sure that the floor is solid enough to support the machine.

- Wear protective helmet, leather gloves or similar protective equipments when moving, installing or cleaning the machine.

- Use only proper movement equipment for it if the moving object weighs over 25kgs

- Don’t put any part of your body on the moving parts of the machine or near to them.

- The operation person have better no long hair

- Don’t wear hand ring, watch, loose clothes, slippery shoes while operating.

- While operation, Debris may fly off. So please wear a protective mask to prevent from being injured.

- Don’t use the machine in a explosive environment.

- A risk of being squeezed is composed when the gearbox and the arm are descending or the spindle is descending to the worktable.