Drills are commonly used in woodworking, metalworking, construction and do-it- yourself projects. Specially designed drills are also used in medicine, space missions and other applications. Drills are available with a wide variety of performance characteristics, such as power and capacity.

What we call a pillar drill is also known as a drill press. It is a tool that allows the operator a steady workplace that will secure the material that is being worked on. Drill press is commonly used where accurate and repeatable production drilling is required. Also in unusual situations where control and different drilling tools are needed. In the application of Power Drill the material could be wood, plastic, or metal- which determines the type of drill bit to be used.

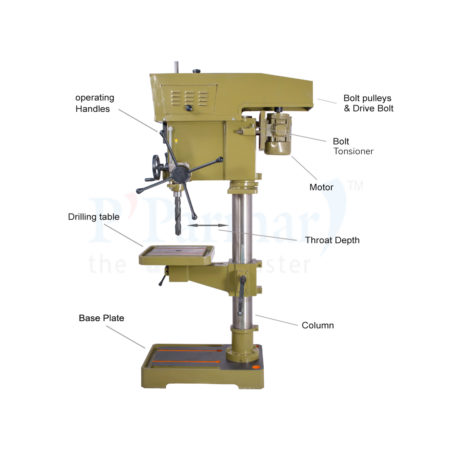

Drill press is the drill machine that can be stand mounted or fixed with floor or

workbench through bolting. Pillar drill consists of base, column, table, drill head

and spindle. Here is a glance on it…..

This drill press uses induction motor supply to execute the drilling operation faster with small or bigger drill bit. It has a motor driven head that has chuck that accepts bits and cutters. Drill press is quite lighter and efficient for operator compare to hand drill. The clamping of drill press makes the convenient positioning for precision and accurate drilling operation. The drill press is operated by pulling a rotary lever which lowers the drill bit/cutter into the work material.

For most operations, it is essential that the table of the drill press is horizontal. The drill press can only move the drill up or down vertically. Some kind of clamping device assures that the work piece will not be thrown off position.

This allows the operator to start the drill by pushing a button, and then use one hand to bring the bit into contact with the material. The advantage is in the precision that the holes drilled will always be at right angles to the surface at the point of contact.

The drill press gives a number of other advantages over a hand held drill :

- Controlled pressure using a rotary feed handle, ability to hold the work, and accurate angle drilling (perfect 90° perpendicular holes in thicker material or precise angles by tilting the table).

- Usually they have a much more powerful motor than hand held drills.

- Use of a fence attached to the table and stops allows rapid repeated drilling of holes in a line.

- Can mount a large number of sizes and types of drills and drill bits or other rotating tools.

- A great number of rotary speed (anywhere from 3 to 15 speed from about 150 RPM to 3000 RPM or more) that can be used, which is critical for making clean holes in different types of materials.

Some Precautionary Measures in Pre-Operational use of Pillar Drills

- Check workspace and walkways to ensure a two feet perimeter around the drill press is clear of people, debris and sawdust that may impair traction or footing to avoid slipping and falls.

- Check that the drill chuck guard is in position.

- Ensure the chuck key has been removed from the drill chuck.

- Ensure that all adjustments are made on the drill with the power off and

locked out - Ensure that you are familiar with the operation of the controls and the

location of the E-stop button (emergency stop) - Follow correct clamping procedures to ensure work is secure.

- Faulty equipment must not be used. Immediately report suspected equipment.

- Remove all loose fitting clothing, jewelry and tie back long hair to prevent getting caught in the rotating chuck.

- Wear proper protective equipments:

- Safety glasses with side shields

- Face shield

- Hearing protection

- Safety footwear

- Respirator as large amounts of dust is created.

- Do not wear gloves or anything that would allow the hand or fingers to be wrapped around the revolving bit.

- Long and Loose hair must be contained by a hat or hairnet to prevent contact with moving parts on equipment and machines.

- Keep all guards and covers on the machine when it is on and running.

- Make sure the size of the bit is equal to or less than the capacity of the drill press.

- Insert bit into drill chuck and tighten with the chuck key. Remove chuck key from the drill chuck before starting the drill press.

- Keep hands and fingers at least 3” from rotating drill bits.

- Never reach around or under a rotating drill bit or grab the chuck to stop the drill press. This can result in hand puncture or other serious injury.

- Keep drill bits clean and sharp. Dull drill bits are a common cause of breakage.

- If a drill bit binds, turn off the drill press, lock out and then carefully turn drill chuck backwards by hand to free the drill bit.

- Turn off the drill press and wait for it to stop before walking away from the machine.

- Don’t touch the drill bit and shavings since they are hot immediately after drilling.

- Always clean the drill press table and work area upon completion of the drilling task. Do not use hands or blow the drill shavings, use a bench brush.

Moreover, drill bit rotates can be changed. The speed at which the drill bit needs to rotate usually depends on the piece of material being drilled and the size of the drill bit. SMALL drill bits usually require a fast drilling speed WHILE LARGE drill bits usually require a slow drilling speed. Although drill presses are used mainly for drilling holes, they can also be used for enlarging holes with a boring tool or finishing holes with a reamer. Drill presses for occasional use in general-purpose machine shops usually have only one spindle. For drilling several holes successively or simultaneously in a workpiece, machines with multiple spindles are available.